Does Cold Storage Need Ventilation?

When it comes to cold storage facilities, one of the crucial aspects to consider is ventilation. Proper ventilation plays a significant role in maintaining the integrity and efficiency of cold storage environments. In this article, we will explore the importance of ventilation in cold storage, the factors that influence ventilation requirements, and the best practices to ensure optimal airflow and temperature control within these facilities.

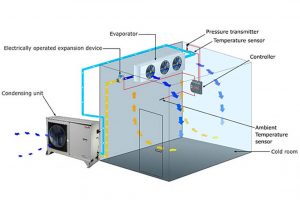

The Importance of Ventilation

Cold storage facilities are designed to maintain specific temperature and humidity levels to preserve perishable goods such as food, pharmaceuticals, and chemicals. These environments require a controlled atmosphere to prevent spoilage, maintain product quality, and adhere to safety regulations. Ventilation in cold storage serves several critical purposes:

1. Temperature Control

One of the primary functions of ventilation in cold storage is temperature control. Proper ventilation helps distribute cool air evenly throughout the storage area, preventing temperature fluctuations and ensuring that goods are consistently maintained at the desired temperature. Without adequate ventilation, pockets of warm air can develop, leading to uneven cooling and potential product spoilage.

2. Humidity Management

Maintaining the right humidity levels is essential in cold storage. Inadequate ventilation can result in moisture buildup, leading to condensation and potential damage to stored goods. Conversely, excessive ventilation can dry out the air, causing product dehydration. Proper ventilation helps strike the right balance, ensuring that humidity levels remain within the desired range. For cold storage ventilation products see this.

3. Air Quality

Ventilation also plays a vital role in maintaining air quality within the cold storage facility. In a closed environment, the buildup of gases and odors from stored products can occur. Effective ventilation helps remove these contaminants, ensuring a safe and odor-free working environment for employees.

4. Energy Efficiency

Properly designed ventilation systems can contribute to energy efficiency in cold storage facilities. By efficiently distributing cool air, these systems reduce the workload on refrigeration equipment, resulting in lower energy consumption and operational costs.

Factors Influencing Ventilation Requirements

The ventilation requirements for cold storage facilities can vary significantly based on several factors. Understanding these factors is crucial for designing an effective ventilation system:

1. Facility Size and Layout

The size and layout of the cold storage facility have a direct impact on ventilation needs. Larger facilities may require more extensive ventilation systems to ensure even airflow throughout the storage area. The layout of shelves, racks, and storage units should also be considered to avoid airflow obstruction.

2. Product Type

The type of products stored in the facility can influence ventilation requirements. Perishable goods with specific temperature and humidity requirements may need more precise ventilation control. Additionally, some products may release gases or odors that require effective ventilation for removal.

3. Temperature Requirements

Different products have varying temperature requirements, and the ventilation system must be tailored to meet these needs. Some goods may require extremely low temperatures, while others need a slightly higher range. Proper ventilation ensures that the desired temperature levels are maintained consistently.

4. Regulatory Compliance

Regulatory agencies often set specific ventilation requirements for cold storage facilities, especially in industries like food and pharmaceuticals. Compliance with these regulations is essential to ensure the safety and quality of stored products. Failure to meet these standards can lead to legal consequences and product recalls.

5. Environmental Factors

Environmental factors, such as the climate and geographic location of the facility, can also impact ventilation needs. Facilities located in hot and humid regions may require more robust ventilation systems to combat external heat and humidity infiltration.

Best Practices for Ventilation

To ensure optimal ventilation in cold storage facilities, consider implementing the following best practices:

1. Conduct a Ventilation Assessment

Before designing or modifying a ventilation system, conduct a thorough assessment of the facility’s needs. Consider the factors mentioned earlier, and work with experts to determine the most suitable ventilation solution.

2. Use High-Quality Ventilation Equipment

Invest in high-quality ventilation equipment that meets the specific requirements of your cold storage facility. Efficient fans, ductwork, and controls are essential for maintaining proper airflow and temperature control.

3. Implement Zoning

Divide the cold storage facility into zones with varying ventilation needs. This allows for more precise control over temperature and humidity in different areas, optimizing energy usage and product preservation.

4. Regular Maintenance and Inspection

Maintain a routine schedule for inspecting and maintaining your ventilation system. Clean or replace filters, check for leaks, and ensure that all components are functioning correctly. Regular maintenance prevents breakdowns and ensures consistent performance.

5. Monitor and Adjust

Implement a monitoring system that tracks temperature, humidity, and air quality within the cold storage facility. Use this data to make necessary adjustments to the ventilation system to maintain optimal conditions.

Conclusion

In storage facilities, ventilation is not just a luxury but a necessity. It plays a crucial role in temperature control, humidity management, air quality, and energy efficiency. By understanding the factors influencing ventilation requirements and implementing best practices, you can create an environment that ensures the preservation of your valuable products while adhering to regulatory standards. Proper ventilation is the key to success in the world of storage.

Recent Comments