What is the Best Warehouse Design Layout?

Warehouses are the logistical backbone of countless businesses, serving as storage, distribution, and fulfillment centers for a wide range of products. The layout of a warehouse can significantly impact its efficiency, productivity, and overall success. In this article, we will explore the key factors to consider when designing a warehouse layout and discuss various types of warehouse design layouts, including their advantages and disadvantages.

Key Factors in Warehouse Design

When it comes to designing a warehouse layout, several key factors must be taken into consideration. These factors influence the overall functionality and efficiency of the facility:

1. Space Utilization

Optimizing space utilization is a fundamental aspect of warehouse design. Efficient use of available space can lead to cost savings and increased storage capacity. Factors to consider include the arrangement of racks, shelving, and storage areas, as well as the use of vertical space through mezzanines and multi-level storage systems.

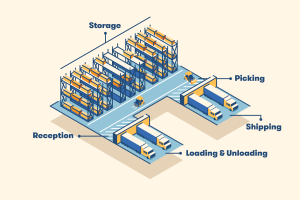

2. Accessibility and Flow

The flow of goods and personnel within the warehouse is critical. Efficient pathways, clear signage, and organized traffic flow can improve productivity and reduce the risk of accidents. The choice of equipment, such as forklifts and conveyor systems, should also be considered in relation to the layout.

3. Product Handling

Different products require different handling and storage solutions. It’s important to categorize products based on their characteristics, such as size, weight, fragility, and storage requirements. This categorization will inform decisions on the type of storage equipment and shelving to use.

4. Inventory Management

Effective inventory management is crucial for minimizing stockouts, overstock, and operational costs. The warehouse layout should support efficient order picking and restocking processes, as well as provide clear visibility into inventory levels.

5. Future Expansion and Adaptability

A well-designed warehouse layout should be adaptable to accommodate changes in the business’s needs. Whether you anticipate future growth or fluctuations in demand, the layout should be designed to handle such changes without a complete overhaul.

6. Safety and Compliance

Safety regulations and compliance standards must be a top priority. Warehouses should be designed to ensure the safety of personnel, and compliance with local and national regulations is essential.

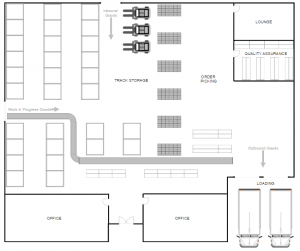

Types of Warehouse Design Layouts

There are several common warehouse design layouts, each with its own advantages and disadvantages. The choice of layout depends on the specific needs of the business and the products it handles. Here are some of the most popular warehouse layouts:

1. Single Aisle (Straight-Line) Layout

In a single aisle layout, shelves or racks are placed in a single row with a central aisle for picking and transporting goods. This layout is space-efficient and offers easy access to products, making it suitable for businesses with a large number of SKUs (Stock Keeping Units). However, it may not be the most efficient option for high-volume operations.

2. Double Aisle (Back-to-Back) Layout

A double aisle layout consists of two parallel rows of shelves with a central aisle in between. This design provides improved accessibility compared to the single aisle layout, making it more suitable for high-volume order picking. It can be space-intensive, but it offers better flow and flexibility.

3. Cross-Docking Layout

Cross-docking is a layout designed for quick product transfer. In this setup, goods arrive on one side and are immediately loaded onto outbound trucks on the other side. This layout minimizes storage needs and is ideal for businesses focused on rapid distribution and just-in-time inventory.

4. Bulk Storage Layout

Bulk storage layouts are ideal for storing large quantities of a single product. Products are often stored on pallet racks or stacked directly on the floor. This layout is efficient for businesses with high inventory turnover and a limited number of product types.

5. High-Density Storage Layout

High-density storage layouts maximize vertical space by using mezzanines, multi-level racks, and automated storage and retrieval systems (AS/RS). This design is suitable for businesses with limited floor space, as it allows for more efficient storage of a wide range of products. https://commgen.com.au/latest-updates/

Choosing the Best Warehouse Layout

The best warehouse layout for your business will depend on a combination of factors, including the type of products you handle, the volume of goods you manage, and your specific operational requirements. Here are some guidelines to help you make an informed decision:

1. Analyze Your Inventory

Thoroughly analyze your inventory to understand its size, weight, and storage requirements. Categorize products based on these factors to determine the best storage solutions for each category.

2. Consider Operational Needs

Evaluate your business’s operational needs, such as order picking processes, inventory turnover rates, and expected growth. This will help you choose a layout that supports your daily operations and future expansion.

3. Seek Professional Guidance

Consider consulting with a warehouse design professional or an industrial engineer. They can provide valuable insights and help you create an efficient layout tailored to your business.

4. Plan for Flexibility

Design your warehouse layout with adaptability in mind. Flexibility is essential to accommodate changes in your business, such as new product lines, seasonal variations, or growth.

5. Prioritize Safety and Compliance

Ensure that your chosen layout complies with safety regulations and provides a safe working environment for your employees. Safety should always be a top priority.

In conclusion, the best warehouse design layout is not a one-size-fits-all solution. It depends on your business’s unique requirements, inventory characteristics, and operational processes. By carefully considering space utilization, accessibility, product handling, inventory management, adaptability, and safety, you can select the layout that maximizes efficiency and productivity for your specific needs.

Recent Comments