The Journey of Cold Storage in the Supply Chain

Cold storage plays a critical role in the modern supply chain, particularly for industries dealing with perishable goods such as food, pharmaceuticals, and biotechnology. From the farm or manufacturer to the final consumer, cold storage ensures that products are preserved at the right temperature throughout their journey. This article delves into the importance of cold storage in the supply chain, its impact on product quality and safety, and the various stages of cold storage within the supply chain.

Understanding the Role of Cold Storage in the Supply Chain

Cold storage involves the controlled storage of temperature-sensitive products, using refrigeration or freezing techniques, to prevent spoilage and preserve product quality. These products, which range from fresh produce to pharmaceuticals and vaccines, are highly sensitive to temperature fluctuations, which can affect their safety, shelf life, and overall quality.

In today’s globalized supply chains, cold storage is integral to maintaining the integrity of goods as they travel from one point to another, often over long distances. The rise of e-commerce, globalization of food markets, and the demand for fresh products has heightened the need for efficient and reliable cold storage solutions.

Without a robust cold storage infrastructure, supply chains would be vulnerable to spoilage, contamination, and significant financial loss. For example, food products that are not stored properly may face bacterial growth, while temperature-sensitive drugs could lose their potency or become ineffective.

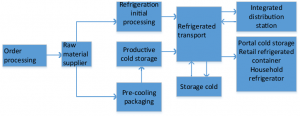

The Key Stages of Cold Storage in the Supply Chain

Cold storage operates across various stages of the supply chain. The journey typically begins at the point of production, moves through various distribution points, and ends with the consumer. At each stage, maintaining the correct temperature is essential for preserving the quality of the product.

1. From Farm or Manufacturer to Distribution Center

The journey begins at the farm, factory, or manufacturing plant, where fresh or temperature-sensitive products are produced. At this stage, products are harvested, packaged, and often placed in refrigerated storage to preserve their freshness before they are transported to distribution centers.

For example, fresh fruits and vegetables are typically harvested and immediately moved to cold storage facilities to slow down their natural ripening process and reduce the growth of bacteria and mold. Similarly, pharmaceutical products such as vaccines are often stored in tightly controlled environments to ensure they remain effective during transit.

Once the products are ready for distribution, they are moved from these primary storage facilities to larger distribution centers. These centers serve as key hubs where goods are further stored until they are shipped out to retailers, wholesalers, or directly to consumers.

2. The Role of Refrigerated Transportation

After leaving the distribution center, products need to be transported to various locations, such as retail outlets, wholesalers, or directly to customers. Refrigerated transportation, or “reefers,” plays a vital role in this stage of the journey.

Refrigerated trucks, shipping containers, and railcars are designed to maintain a constant temperature, protecting the products from temperature fluctuations during transit. These modes of transportation are equipped with sophisticated temperature monitoring systems that allow operators to track and adjust temperatures in real time, ensuring that perishable goods remain safe and fresh throughout their journey.

For example, pharmaceuticals, which often require a specific temperature range to remain viable, are transported in refrigerated containers to maintain that critical temperature. Any deviation from this range could lead to compromised product quality and safety.

3. Last-Mile Delivery: Ensuring Freshness at the Consumer Level

The final leg of the cold storage journey is the last mile, where products are delivered to retailers, wholesalers, or directly to consumers. In this phase, cold storage operations are crucial for ensuring that products reach consumers in their freshest, most intact state.

For retailers, refrigerated storage and display cases help maintain the ideal temperature for products like dairy, meat, and frozen goods. Similarly, many consumers now expect their food deliveries to arrive fresh and in a safe condition, prompting e-commerce platforms to adopt temperature-controlled packaging for direct-to-consumer deliveries.

With the rise of online grocery shopping and food delivery services, last-mile cold storage has become even more important. To accommodate this growing demand, companies are investing in temperature-controlled packaging and delivery vehicles, as well as sophisticated tracking systems to monitor product conditions.

Challenges Faced in Cold Storage Across the Supply Chain

While cold storage is indispensable in the supply chain, it comes with its share of challenges. Several factors can impact the efficiency and effectiveness of cold storage operations, including:

1. Temperature Control and Fluctuations

One of the biggest challenges in cold storage is maintaining a constant temperature. Even small fluctuations can cause significant problems, including spoilage, contamination, and reduced shelf life of products. For instance, if frozen goods are thawed during transit and then refrozen, it can compromise their texture, taste, and safety.

To mitigate this, cold storage facilities, transportation systems, and last-mile delivery methods must incorporate robust temperature monitoring and control systems. These systems help ensure that products remain within the specified temperature range, preventing spoilage or product degradation.

2. Energy Consumption and Sustainability

Cold storage facilities are energy-intensive, contributing to high operational costs and carbon emissions. With growing concerns about climate change, many industries are focusing on sustainability in cold storage operations. The need for energy-efficient refrigeration systems, the use of renewable energy sources, and the reduction of food waste are all key considerations.

For example, many companies are adopting energy-efficient cooling technologies, such as variable speed compressors, LED lighting, and refrigeration systems that use natural refrigerants like CO2. In addition, integrating solar panels or wind energy into cold storage facilities can help reduce reliance on traditional, non-renewable power sources.

3. Maintaining Food Safety and Compliance

For perishable products such as food and pharmaceuticals, safety and regulatory compliance are critical. Cold storage facilities must adhere to strict standards to ensure that products are stored at the correct temperature and handled properly throughout the supply chain.

In the food industry, the U.S. Food and Drug Administration (FDA) and other regulatory bodies set stringent guidelines for the storage and transportation of perishable products. Non-compliance can result in fines, spoilage, or even legal consequences.

Pharmaceutical companies also face strict regulatory requirements, including temperature-controlled transport and storage for vaccines, insulin, and other temperature-sensitive medications. These regulations are in place to protect consumer health and ensure that products maintain their efficacy.

Future Trends in Cold Storage within the Supply Chain

As technology continues to evolve, the cold storage industry is undergoing significant changes that aim to increase efficiency, sustainability, and reliability. Some key trends shaping the future of cold storage include:

1. Automation and Smart Technology

The introduction of automation and smart technologies is transforming cold storage operations. Automated systems for inventory management, refrigeration control, and temperature monitoring are becoming more widespread. These systems use real-time data to optimize storage conditions, improve efficiency, and reduce the risk of human error.

Smart sensors and IoT devices are being integrated into cold storage equipment, allowing for remote monitoring of temperature, humidity, and other environmental factors. In case of any deviation from optimal conditions, alerts can be sent to operators to take immediate action.

2. Sustainable and Energy-Efficient Cold Storage

As mentioned earlier, sustainability is becoming a major priority in the cold storage industry. Future cold storage facilities will likely see more widespread use of energy-efficient refrigeration systems, renewable energy sources, and eco-friendly refrigerants. Businesses are increasingly seeking ways to reduce energy consumption while maintaining high standards for product preservation.

3. Blockchain for Traceability

Blockchain technology is gaining traction in the supply chain industry, including cold storage. By providing a transparent and immutable ledger of product movements, blockchain helps ensure that goods are stored, transported, and handled according to strict guidelines.

Blockchain can also assist in verifying the temperature conditions of products at each stage of the supply chain. This provides consumers with greater confidence in the safety and quality of the products they purchase.

Conclusion

Cold storage plays an essential role in the modern supply chain, ensuring the safe and efficient transportation and storage of perishable goods. From the farm to the consumer, cold storage systems are vital for maintaining product quality, safety, and compliance with industry regulations. While challenges such as temperature control, energy consumption, and food safety remain, technological innovations are helping to drive the future of cold storage. As the supply chain continues to evolve, cold storage will remain at the forefront of ensuring that products reach consumers fresh, safe, and of the highest quality.

Recent Comments