The Crucial Components of Cold Chain Management

In today’s globalized world, the efficient transportation and storage of temperature-sensitive products have become paramount. From pharmaceuticals to fresh produce, maintaining a consistent and controlled temperature throughout the supply chain is crucial to ensure product quality and safety. This process, known as the cold chain, relies on several key components to guarantee the integrity of the goods being transported. Let’s delve into the three main components that constitute the foundation of the cold chain. What are the 3 main components of cold chain?

1. Temperature-Controlled Storage Facilities

At the heart of the cold chain lie temperature-controlled storage facilities, which act as the initial line of defense against temperature fluctuations. These facilities, commonly referred to as cold storage or refrigerated warehouses, are equipped with advanced cooling and monitoring systems to regulate temperatures within specific ranges. The precise temperature control is essential to prevent spoilage, maintain product quality, and ensure that goods reach their destination in optimal condition.

Cold storage facilities are strategically designed to accommodate various products with distinct temperature requirements. For example, pharmaceuticals may require ultra-low temperatures, while fruits and vegetables may need slightly higher but still controlled environments. The ability to tailor storage conditions to the unique needs of different products is a hallmark of effective cold chain management.

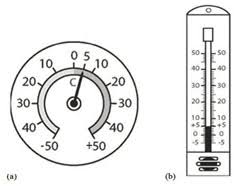

In addition to temperature regulation, these facilities incorporate advanced monitoring technologies. Temperature sensors, data loggers, and real-time monitoring systems play a pivotal role in ensuring that any deviations from the prescribed conditions are promptly identified and addressed. This level of vigilance is critical in averting potential damage to sensitive products and maintaining the overall integrity of the cold chain.

2. Refrigerated Transportation Systems

The second key component of the cold chain is refrigerated transportation systems. Once products leave the secure confines of storage facilities, they enter the dynamic environment of transportation. Whether by road, sea, air, or rail, maintaining the required temperature during transit is imperative to safeguard the products from deterioration.

Refrigerated trucks, containers, and cargo holds are specially designed to provide a seamless extension of the temperature-controlled environment established in storage facilities. These vehicles are equipped with robust cooling systems that can withstand external weather conditions and ensure that the internal temperature remains constant. The efficiency of insulation and refrigeration mechanisms is paramount to guaranteeing the uniformity of the cold chain across the entire supply route.

Furthermore, advancements in transportation technology have led to the development of smart and connected refrigeration systems. These systems enable real-time monitoring of temperature conditions during transit, allowing stakeholders to track and manage the integrity of the cold chain remotely. This proactive approach enhances responsiveness to potential issues, minimizing the risk of product spoilage and ensuring the safe delivery of goods to their destination.

3. Stringent Quality Assurance Protocols

While temperature control is the backbone of the cold chain, ensuring product quality and safety demands the implementation of stringent quality assurance protocols. This third component involves comprehensive measures at every stage of the supply chain to mitigate risks and maintain the highest standards of quality.

Quality assurance begins with the careful selection of suppliers and extends to rigorous inspection and testing of incoming raw materials or products. This initial scrutiny sets the foundation for the entire cold chain process. Regular audits and assessments of storage facilities and transportation systems are conducted to identify and address any potential vulnerabilities.

Documentation and record-keeping play a crucial role in quality assurance, providing a traceable history of the product’s journey through the cold chain. This includes temperature logs, handling procedures, and any incidents or deviations encountered along the way. The ability to trace the origin and handling of a product is instrumental in identifying and resolving issues that may compromise its quality.

Training and certification of personnel involved in the cold chain are also integral to maintaining quality standards. From warehouse staff to transportation professionals, ensuring that individuals are well-versed in the specific requirements of handling temperature-sensitive products is essential. Continuous training programs keep personnel updated on the latest industry standards and best practices.

Conclusion

In conclusion, the cold chain is a complex and finely tuned system that relies on the seamless integration of temperature-controlled storage facilities, refrigerated transportation systems, and stringent quality assurance protocols. These three main components work in harmony to ensure that products requiring specific temperature conditions reach their destination in optimal condition.

As the demand for temperature-sensitive products continues to rise, the importance of an efficient and reliable cold chain becomes increasingly evident. Stakeholders across industries must invest in cutting-edge technologies, robust infrastructure, and comprehensive training to uphold the integrity of the cold chain and meet the growing expectations of consumers for high-quality, safe, and fresh products. By prioritizing these components, businesses can navigate the challenges of global supply chains and contribute to the sustainability and success of the cold chain industry.

Recent Comments