Understanding Cold Storage Room Sizes

Cold storage rooms play a crucial role in various industries, from food preservation to pharmaceuticals. Understanding the different sizes and specifications of cold storage rooms is essential for ensuring optimal storage conditions and operational efficiency. This guide will explore the key factors influencing cold storage room sizes, types of cold storage, and how to determine the right size for your needs.

Factors Influencing Cold Storage Room Sizes

The size of a cold storage room depends on several factors. These include the type of products being stored, the volume of goods, and specific environmental requirements. Here are some critical factors to consider:

1. Type of Products

The nature of the products being stored heavily influences the required cold storage room size. Perishable items like fruits and vegetables require different conditions compared to pharmaceuticals or frozen goods. For instance, a room designed for fresh produce may need to maintain higher humidity levels and slightly warmer temperatures compared to one intended for frozen foods.

2. Volume of Goods

Accurately estimating the volume of goods to be stored is essential for determining the appropriate room size. This involves calculating the total volume of inventory, taking into account factors like packaging dimensions and the arrangement of products within the room. Overestimating or underestimating storage needs can lead to inefficient use of space and increased operational costs.

3. Environmental Requirements

Different products have specific temperature and humidity requirements. Understanding these requirements helps in selecting the right refrigeration system and room design. For instance, pharmaceutical cold storage might require precise temperature control and low humidity levels to ensure product stability and efficacy.

Types of Cold Storage Rooms

Cold storage rooms come in various types, each designed to meet specific needs. Understanding the differences between these types helps in selecting the best option for your storage requirements.

1. Walk-In Coolers

Walk-in coolers are a common choice for businesses requiring moderate cold storage. These rooms are typically used for storing fresh produce, dairy products, or beverages. They are designed to allow personnel to enter and access stored goods. The size of walk-in coolers can vary widely, from small units suitable for a single restaurant to larger versions for supermarkets or warehouses.

2. Walk-In Freezers

Walk-in freezers are designed for long-term storage of frozen goods. These rooms maintain temperatures below 0°F (-18°C) and are essential for preserving food items for extended periods. Walk-in freezers often come with heavy-duty insulation and specialized refrigeration systems to handle the lower temperatures required. https://commgen.com.au/contact-us/

3. Modular Cold Storage Rooms

Modular cold storage rooms are customizable and can be expanded or modified as needed. They are ideal for businesses with fluctuating storage needs or those requiring specialized configurations. Modular units offer flexibility in design and can be tailored to specific temperature and humidity requirements.

Determining the Right Size for Your Cold Storage Room

Choosing the right size for a cold storage room involves several steps. By carefully assessing your needs and considering key factors, you can make an informed decision that ensures efficient operation and optimal storage conditions.

1. Assess Your Storage Needs

Begin by evaluating the types and volumes of products you need to store. Consider factors such as product turnover rates, seasonal variations, and future growth projections. This assessment will help you determine the minimum and maximum storage capacities required.

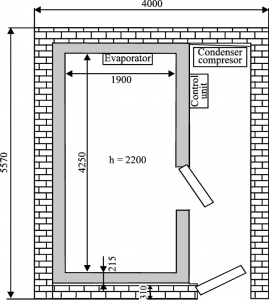

2. Calculate the Required Space

To calculate the required space, measure the volume of your inventory and account for additional space needed for proper ventilation and accessibility. Utilize shelving or racking systems to maximize space utilization and ensure efficient organization within the cold storage room.

3. Consult with Professionals

Consulting with cold storage professionals or engineers can provide valuable insights into designing a room that meets your specific requirements. They can help with selecting appropriate refrigeration systems, insulation materials, and layout designs to optimize performance and energy efficiency.

Maintenance and Operational Considerations

Once you have determined the right size for your cold storage room, ongoing maintenance and operational practices are essential for ensuring its efficiency and longevity.

1. Regular Inspections

Conduct regular inspections to identify any issues with the refrigeration system, insulation, or structural integrity of the cold storage room. Addressing potential problems early can prevent costly repairs and ensure consistent performance.

2. Energy Efficiency

Implement energy-efficient practices to reduce operational costs and environmental impact. This may include using energy-efficient refrigeration units, optimizing temperature settings, and ensuring proper insulation to minimize energy loss.

3. Hygiene and Sanitation

Maintaining a clean and hygienic environment within the cold storage room is crucial for preserving product quality and preventing contamination. Establish regular cleaning protocols and ensure that all equipment is properly sanitized.

Conclusion

Understanding cold storage room sizes involves considering various factors, including the type of products, volume of goods, and environmental requirements. By carefully assessing your needs and consulting with professionals, you can determine the right size and type of cold storage room to ensure optimal storage conditions and operational efficiency. Regular maintenance and energy-efficient practices further enhance the effectiveness and longevity of your cold storage solution.

Recent Comments