Cold Storage Requirements: What Your Building Must Have

Cold storage facilities are a critical component in industries ranging from food and pharmaceuticals to logistics and e-commerce. The effectiveness of a cold storage operation is heavily influenced by the building itself. From temperature control to insulation, the right infrastructure ensures product quality, regulatory compliance, and operational efficiency. In this article, we’ll explore the essential requirements for buildings designed for cold storage and what you should consider when planning or retrofitting a facility.

Understanding Cold Storage Needs

Before diving into specific building requirements, it’s important to understand why cold storage is so crucial. Products stored in cold conditions, such as perishable food items, pharmaceuticals, and sensitive chemicals, require strict temperature and humidity control. Even minor fluctuations can lead to spoilage, reduced shelf life, or regulatory non-compliance.

Temperature Control

A primary consideration is maintaining consistent temperatures. Depending on the product, cold storage facilities may require:

Chilled storage (0°C to 5°C / 32°F to 41°F): Typically for fresh produce, dairy, and some beverages.

Frozen storage (-18°C / 0°F or lower): For meat, seafood, frozen food products, and pharmaceuticals.

Ultra-low temperature storage (-80°C / -112°F): Often used for vaccines, certain biologics, and research samples.

The building must support reliable refrigeration systems capable of maintaining these temperatures, with redundancy to avoid costly failures.

Humidity Control

In addition to temperature, humidity is a vital factor. Excess moisture can cause frost buildup, spoilage, or mold growth, particularly in food storage. The building must accommodate proper dehumidification systems and ventilation to maintain optimal conditions for the stored products.

Structural Requirements for Cold Storage Buildings

Not all buildings are suitable for cold storage. The structural design impacts insulation, energy efficiency, and long-term operational costs.

Insulation

A high-quality insulation system is one of the most critical components of a cold storage facility. Proper insulation reduces energy consumption, maintains temperature consistency, and prevents condensation. Common materials include:

Polyurethane panels: Excellent thermal resistance and widely used in commercial cold storage.

Polystyrene panels: Cost-effective and suitable for moderate temperature ranges.

Spray foam insulation: Ideal for irregular spaces and retrofits.

Insulation thickness varies depending on the storage temperature required. For example, ultra-low temperature storage often requires thicker panels than chilled storage.

Flooring

Cold storage floors must handle heavy loads while providing thermal insulation. Popular options include:

Reinforced concrete floors: Durable and able to handle forklift traffic.

Insulated flooring panels: Prevent heat transfer from the ground, maintaining consistent internal temperatures.

Additionally, slip-resistant coatings or textured surfaces are important for safety in areas prone to frost or moisture.

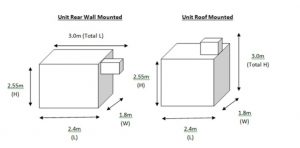

Wall and Roof Design

Walls and roofs should minimize thermal bridging, which can compromise temperature control. Continuous insulation and sealed joints are essential to prevent air leakage. Roofs often require:

Reflective coatings to reduce heat absorption.

Proper drainage systems to prevent water accumulation that could affect insulation.

Mechanical and Electrical Requirements

Beyond the structure itself, the mechanical and electrical systems of a cold storage building play a crucial role in maintaining operational efficiency.

Refrigeration Systems

Cold storage facilities require industrial-grade refrigeration units. Key considerations include:

Capacity: Must meet peak cooling requirements without overloading the system.

Redundancy: Backup systems ensure continuous operation during maintenance or power failure.

Energy efficiency: Variable speed compressors and modern refrigeration technology reduce operating costs.

Lighting

Lighting in cold storage areas must be carefully planned to minimize heat generation while providing adequate visibility. LED lighting is preferred due to its low heat output and energy efficiency.

Power Supply and Backup

Reliable electricity is critical. Cold storage buildings should have:

Stable main power supply capable of supporting all refrigeration and mechanical systems.

Backup generators or battery systems to maintain operations during outages.

Safety and Regulatory Compliance

Cold storage buildings must comply with industry regulations to ensure both safety and product quality.

Fire Safety

Fire suppression in cold storage facilities presents unique challenges because water-based sprinklers can damage stored products. Solutions include:

Clean agent fire suppression systems that do not harm stored goods.

Proper fire-rated insulation materials to prevent rapid spread of fire.

Health and Sanitation

Cold storage facilities, especially for food and pharmaceuticals, must maintain high sanitation standards. Requirements include:

Smooth, non-porous surfaces for easy cleaning.

Pest control measures such as sealed entrances and proper ventilation.

Drainage systems to prevent water accumulation.

Operational Considerations

Even the most well-designed building can fail if operational needs are not considered during planning.

Accessibility and Layout

The building layout should allow easy movement of goods, forklifts, and personnel. Considerations include:

Wide aisles and clearance space for machinery.

Separate zones for chilled and frozen storage to prevent temperature cross-contamination.

Scalability

Future growth should influence the choice of building. Modular designs allow expansion without major structural changes, ensuring that your facility can adapt to increasing storage demands.

Energy Efficiency

Cold storage facilities are energy-intensive. Features like high-quality insulation, energy-efficient refrigeration, LED lighting, and smart climate controls reduce operational costs and environmental impact.

Conclusion

Choosing the right building for cold storage is far more than a construction decision—it directly affects product quality, operational efficiency, and long-term costs. Essential requirements include:

Consistent temperature and humidity control

High-quality insulation, flooring, and wall systems

Reliable refrigeration, power, and lighting systems

Compliance with fire safety, sanitation, and regulatory standards

Operational efficiency, scalability, and energy management

By carefully considering these factors, businesses can ensure their cold storage facility is equipped to handle current needs while remaining adaptable for future growth. The right building is not just a shelter—it’s the backbone of a successful cold storage operation.

Recent Comments