Building a cold storage room is a complex process that requires careful planning and consideration of various factors, including the types of materials used in its construction. The materials you choose will impact the room’s energy efficiency, durability, and ability to maintain the desired temperature for storing perishable goods. This article will explore the key materials commonly used in cold storage construction, their benefits, and why selecting the right materials is crucial for the long-term effectiveness of the storage facility.

Key Materials for Cold Storage Room Construction

Cold storage rooms are specially designed to preserve perishable goods such as food, pharmaceuticals, and other sensitive products. To ensure these rooms function effectively, the construction materials must meet specific requirements such as high insulation properties, resistance to moisture, and durability in low-temperature environments. The following materials are commonly used in cold storage room construction:

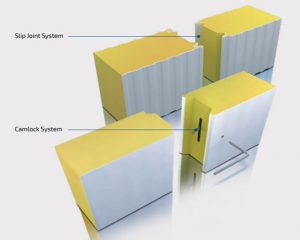

Insulated Panels

One of the most crucial elements in cold storage construction is the insulation material. Insulated panels are often used for walls, ceilings, and floors in cold storage rooms. These panels typically consist of a metal skin (often galvanized steel or aluminum) and an insulating core made of materials like expanded polystyrene (EPS), polyurethane (PUR), or mineral wool.

The primary function of insulated panels is to reduce heat transfer, which helps maintain a consistent internal temperature while minimizing energy consumption. The better the insulation, the less energy is required to keep the room at the desired temperature. For instance, polyurethane panels offer a higher R-value (thermal resistance) compared to EPS panels, making them ideal for colder environments where energy efficiency is critical.

Flooring Materials

The flooring in cold storage rooms must be durable, non-slip, and resistant to cold temperatures and moisture. The most common flooring materials for cold storage include:

Concrete: Concrete is a durable, strong, and cost-effective choice for cold storage floors. It can withstand the weight of heavy pallets and equipment while providing a solid, long-lasting surface. However, concrete must be properly sealed to prevent moisture absorption and maintain hygiene.

Epoxy Coatings: Epoxy coatings are often applied to concrete floors in cold storage rooms to create a smooth, seamless, and moisture-resistant surface. These coatings are easy to clean and maintain, and they provide an additional layer of protection against wear and tear.

Polyurethane Flooring: Polyurethane is a highly durable and flexible material that is often used for cold storage room floors, especially in facilities that handle heavy traffic. It is resistant to chemicals, abrasion, and temperature extremes, making it an excellent choice for areas exposed to cold, moisture, and heavy equipment.

Doors and Seals

Cold storage doors play a significant role in maintaining the room’s internal temperature and ensuring that cold air doesn’t escape. These doors are typically made from insulated materials, such as polyurethane or polystyrene foam, and are designed to provide an airtight seal when closed.

The quality of the door seals is also crucial for preventing the loss of cold air and maintaining energy efficiency. Seals made from rubber, silicone, or other high-quality materials help ensure that the doors are tightly closed and airtight. Additionally, automatic doors with motion sensors are commonly used in high-traffic cold storage areas to minimize the time the doors are open and reduce energy loss.

Other Essential Materials for Cold Storage Room Construction

While insulation, flooring, and doors are the primary materials used in cold storage construction, several other materials are equally important in creating a functional and efficient storage environment.

Walls and Ceilings

As with the floors, the walls and ceilings of cold storage rooms must be insulated to prevent heat transfer and ensure a consistent temperature. Insulated metal panels (IMP) are a popular choice for both walls and ceilings. These panels are durable, resistant to moisture, and easy to clean, making them ideal for maintaining sanitary conditions in cold storage environments.

In some cases, cold storage rooms may also have additional layers of insulation, such as fiberglass or spray foam, to enhance the thermal performance and reduce energy consumption.

Refrigeration Systems

A reliable refrigeration system is essential to keeping a cold storage room at the required temperature. While refrigeration units themselves are not considered a “material” for building, they are a critical component of the overall cold storage infrastructure. Refrigeration systems often use air-cooled or water-cooled compressors and evaporators to maintain the cold temperatures necessary for preserving products.

The type of refrigeration system used will depend on the size of the cold storage room, the temperature requirements, and the specific goods being stored. For example, larger cold storage facilities may require industrial-scale refrigeration systems, while smaller operations might rely on more compact, self-contained units.

Lighting and Electrical Components

Proper lighting is necessary for cold storage rooms to ensure safety and visibility. Since cold storage rooms often have limited natural light, energy-efficient LED lighting is a common choice. These lights are durable, low-maintenance, and energy-efficient, making them ideal for the demanding conditions of cold storage environments.

Electrical components such as thermostats, control panels, and backup power systems also play a critical role in the operation of cold storage rooms. A reliable power supply is necessary to maintain the refrigeration system and ensure the room stays at the desired temperature.

Why Material Selection Matters

Choosing the right materials for a cold storage room is essential not only for ensuring product quality but also for improving energy efficiency and reducing operational costs. Here’s why material selection is so important:

Energy Efficiency

Cold storage rooms consume a significant amount of energy due to the need for refrigeration and maintaining a consistent temperature. Using high-quality insulation materials, such as polyurethane panels or mineral wool, can drastically reduce the amount of energy required to maintain the desired temperature. This, in turn, leads to lower energy bills and a more environmentally friendly operation.

Durability and Maintenance

Cold storage environments are harsh, with low temperatures and constant exposure to moisture. Selecting durable materials that can withstand these conditions is vital for ensuring the longevity of the facility. Materials like insulated metal panels, epoxy-coated floors, and high-quality door seals all contribute to the overall durability of the cold storage room. Choosing materials that are easy to clean and resistant to wear and tear can also reduce maintenance costs over time.

Compliance with Regulations

Cold storage facilities, particularly those that store food or pharmaceuticals, must comply with various health and safety regulations. Using appropriate materials, such as non-toxic insulation and smooth, non-porous surfaces for walls and floors, ensures that the facility meets hygiene standards. Additionally, materials that are resistant to mold, bacteria, and other contaminants help maintain the safety and quality of stored products.

Conclusion

In conclusion, building an efficient and durable cold storage room requires careful consideration of the materials used in its construction. Insulated panels, flooring materials, doors and seals, and refrigeration systems all play a crucial role in maintaining the desired temperature and preserving the quality of stored goods. By selecting the right materials, facility owners can reduce energy consumption, minimize maintenance costs, and create a safe, reliable storage environment that meets the needs of their business.

Recent Comments